Category: Chain idlers

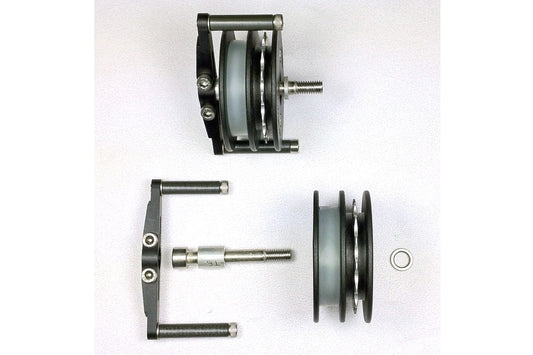

A bicycle chain is designed to run over cogs and will either mill deep notches in guide rollers made of plastic or bounce over the surface with strong vibration. This is where valuable energy is lost due to friction. T-Cycle chain idlers solve this problem by allowing the chain to run on a CNC machined cog made of either aluminum (Sport) or titanium (Elite), reducing friction, wear and vibration of the drive. For many models of the recumbent scene we offer special chain idler sets which include all the parts you need to mount it on your recumbent.

-

Chain idler T-Cycle SPORT

Regular price From €49,00 EURRegular priceUnit price per -

Chain idler T-Cycle ELITE

Regular price From €79,00 EURRegular priceUnit price per -

Chain idler ICE

Regular price €49,00 EURRegular priceUnit price per -

Chain guide T-Cycle

Regular price From €19,00 EURRegular priceUnit price per -

Mini chain idler T-Cycle for quick frame adjust

Regular price €19,00 EURRegular priceUnit price per -

Chain idler set for Optima Baron

Regular price From €89,00 EURRegular priceUnit price per -

Chain idler set T-Cycle for ICE Sprint models

Regular price From €129,00 EURRegular priceUnit price per -

Chain idler set T-Cycle for Metaphysics

Regular price From €119,00 EURRegular priceUnit price per -

Chain idler set for Challenge Fujin SL

Regular price €79,00 EURRegular priceUnit price per -

Chain idler kit for Surly Big Dummy

Regular price From €129,00 EURRegular priceUnit price per -

Chain idler set for Windcheetah

Regular price From €269,00 EURRegular priceUnit price per -

Axle bolt M8 for T-Cycle idler

Regular price €4,90 EURRegular priceUnit price per -

Panhead bolt ICE M8x35

Regular price €4,90 EURRegular priceUnit price per -

Ball bearing for T-Cycle idlers

Regular price From €3,90 EURRegular priceUnit price per -

Spacer T-Cycle for M8 bolt

Regular price €2,90 EURRegular priceUnit price per -

Spacer set M8 T-Cycle

Regular price €19,00 EURRegular priceUnit price per