Most recumbents and trikes require a longer chain than conventional bicycles due to their design. The recumbent riding position requires a greater distance between the crankset and the rear wheel. Chain idlers are used to optimally route the chain along its path. Often recumbents are only equipped with simple plastic idlers without a cog.

A chain bouncing up and down on a plein hard plastic surface is unfortunately not useful at all. Everywhere else in the drivetrain, chainrings and sprockets are in use. Why should your chain idler be any less important? A chain idler without teeth guiding the power side of the chain causes friction and thus loss of power. This can be easily seen when the chain starts to mill deeper and deeper notches into the plastic material of the chain idler. If the plastic is very hard, the chain will even bounce up and down constantly on its way from the rear wheel.

A chain has a very specific shape that is designed to run on a chainring or cog. The shape of a chain idler without teeth would be best suited for a belt drive. However, recumbents and tricycles are typically chain driven and therefore none of the components over which a drive chain passes should look like it was built for a belt drive. As a result, your valuable muscle power is transferred to the rear wheel with little efficiency. That's why we recommend focussing your attention on high quality chain guide components.

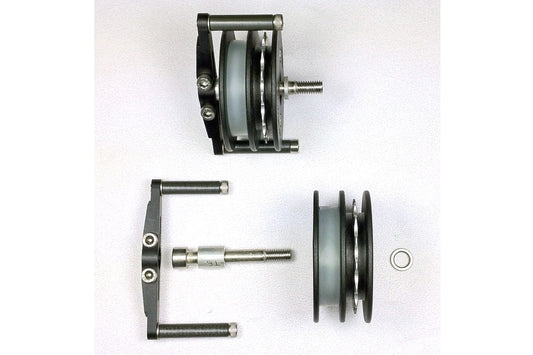

Day in and day out, TerraCycle thinks about chain idlers and works on their further development. Every week customers contact TerraCycle and pass on their experiences. With every conversation, TerraCycle increases its knowledge and experience of chain idlers and chain guides, and it is no exaggeration to say that no one in the recumbent industry has more expertise on this subject than Pat Franz and his dedicated team. Every single chain idler is manufactured in Portland, OR with absolute dedication to detail and quality.